Nuclear 03: How Nuclear Reactors Work

Examining commercial reactor architectures and the strategic constraints behind their designs

Welcome to As Built! This week’s post is part of the nuclear landscape series. So far, we’ve covered nuclear physics and how engineers harness fission. Today is about nuclear reactors—how they’re built and what the different architectures are. Next up will be the nuclear fuel cycle—where uranium comes from and how it’s turned into fuel. That’ll round out the series technical foundation..

Then we’ll shift gears. We’ll explore how Russia’s nuclear exports create diplomatic leverage, how passive safety systems underpin new fission plants, how one metallurgist was behind nuclear proliferation to Pakistan, Libya, Iran, and North Korea, and why the 1970s nuclear boom collapsed and how today’s renaissance might be different.

But for now, how nuclear reactors work!

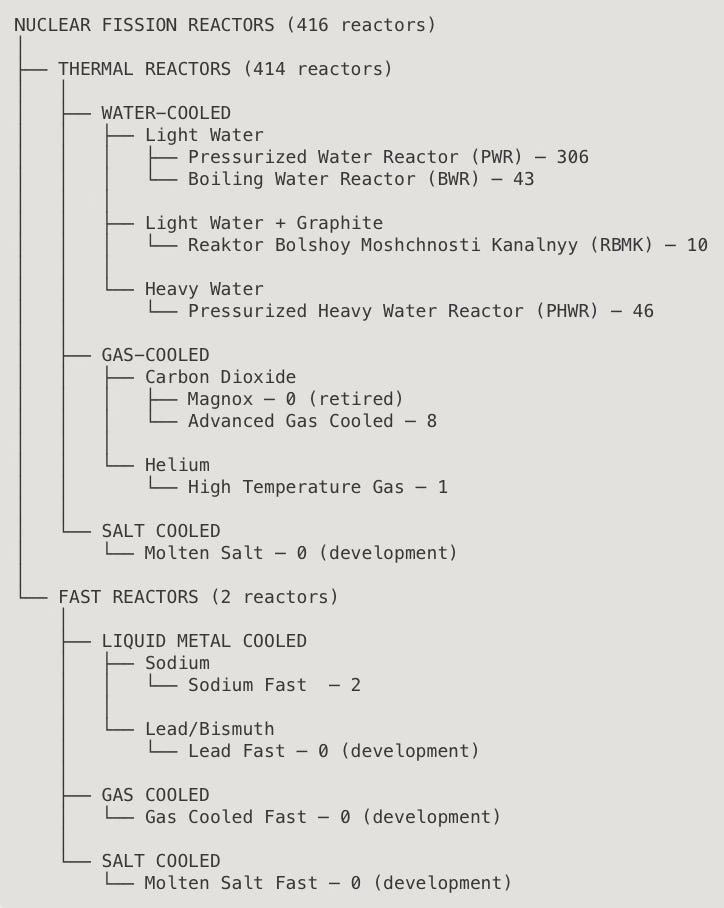

Nuclear reactors come in many shapes and sizes. Of the 416 operating worldwide today, some are cooled with water, others with gas or liquid metal. Some need enriched uranium, others don’t. All harness fission, but their engineering diverges.

The stories behind these differences reveal as much as the physics:

The United States pioneered pressurized water reactors (PWRs) for submarines, then scaled that military technology for civilian power.

France initially built gas cooled reactors to sidestep uranium enrichment, but pivoted to PWRs as operational maturity accumulated.

Canada also avoided enrichment by developing heavy water reactors that run on natural uranium, allowing the country to capitalize on its extensive uranium resources.

Russia operates the world’s only commercial fast reactors that can breed fuel while generating power. But there are only two in operation.

These aren’t just engineering variations. They’re national strategies.

Each architecture reflects its host nation’s technology readiness, supply chains, resource access, and economic reality. What makes sense for one country might be nonsensical for another. These choices are sticky. Many were made decades ago, but still influence which designs dominate, who builds reactors, and who controls the fuel.

Understanding the dynamics behind them will position us to predict where the industry will head next, as many new programs come online.

The Core Elements

Every nuclear reactor follows the same basic process: sustain a fission chain reaction, generate heat, and convert it to electricity. They’re simple goals that require complex execution.

Five subsystems make it possible:

Fuel: Undergoes fission, releases neutrons, and generates heat

Moderator: Slows neutrons to speeds where fission becomes probable

Coolant: Carries heat from the core to the turbines

Power conversion: Transforms thermal energy into electricity

Control: Increases or decreases the rate of fission

These five components can combine to make many design permutations. For example, water can serve as both a moderator and a coolant simultaneously. Conversely, we can use gas as a coolant and graphite as a moderator. Similarly, fuel enrichment levels can vary dramatically.

Surveying the Landscape

We’ll consider twelve different nuclear reactor architectures, and we’ll start by segmenting the reactor landscape by neutron speed into two categories:

Thermal reactors slow neutrons down using moderators like water or graphite, through many collisions between the neutrons and the fluid’s atoms.

Fast reactors operate without moderators, keeping neutrons at the high speeds they’re born with through fission.

Thermal Reactors

About 99.5% of nuclear electricity worldwide comes from thermal reactors, making this category the dominant approach. By slowing the neutrons, thermal reactors enable high uranium-235 fission cross sections, which make chain reactions sustainable with fuel enriched to just 3-5% uranium-235. However, thermal reactors can only burn fuel “once through,” which means that any fuel recycling must happen at a different facility.

Within thermal reactors, we can subdivide by moderator and coolant combination. Some architectures use the same substance for both functions, while others separate them.

Light Water Reactors use ordinary light water (H₂O) as both moderator and coolant. Pressurized Water Reactors (PWR) and Boiling Water Reactors (BWR) are the two standard types of light water reactors. Combined, they represent 90% of all nuclear power generated globally on a per Watt basis.

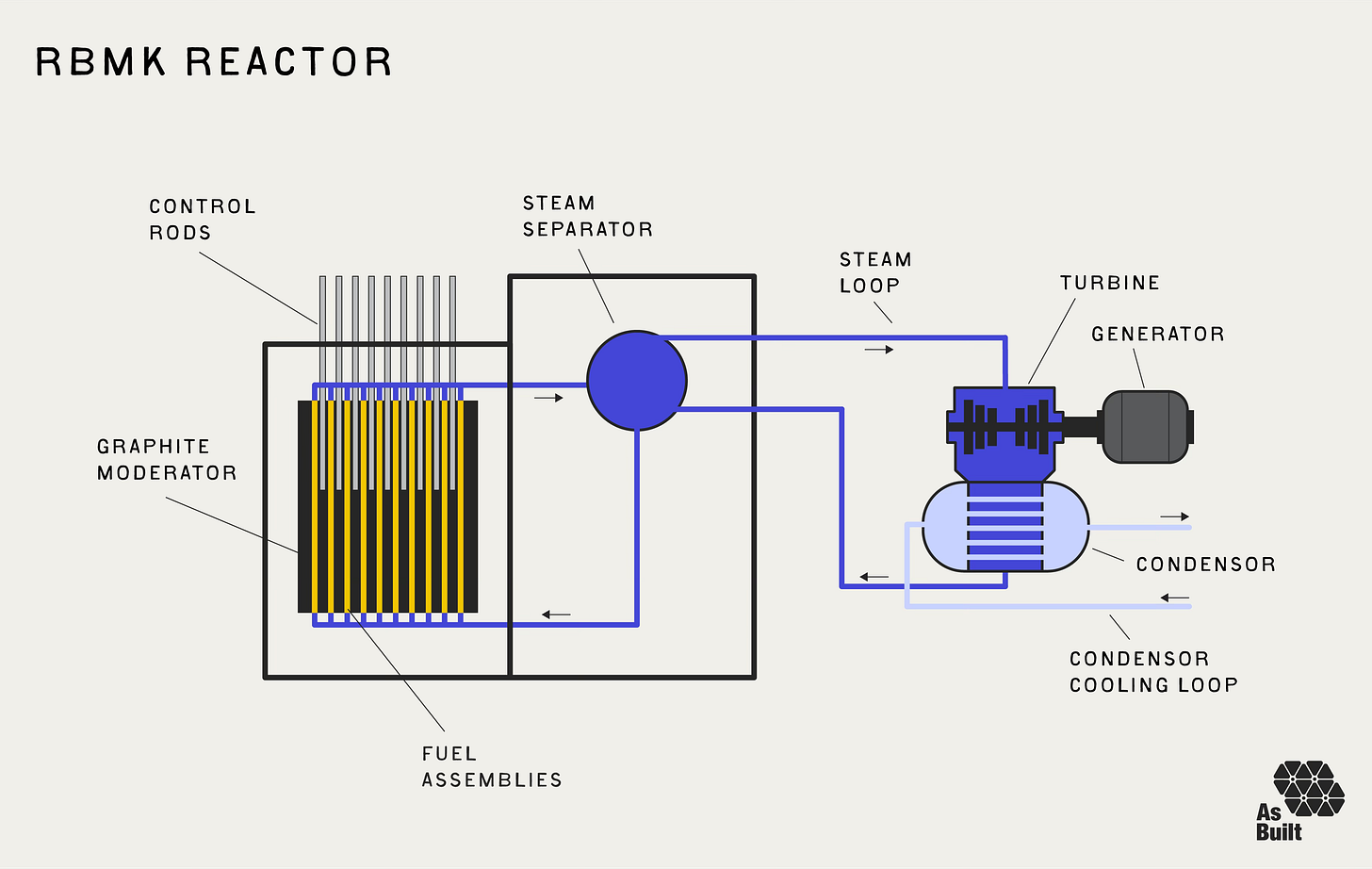

Light Water, Graphite Moderated Reactors use light water as a coolant and graphite as a moderator. Famously, this is the architecture of the Russian RBMK reactor, which was used at Chernobyl. Certain nuances of this design helped contribute to the catastrophic accident.

Heavy Water Reactors use deuterium oxide (D₂O) as both moderator and coolant. Deuterium is a hydrogen isotope with one proton and one neutron, making it a heavier variant of standard hydrogen. This design enables the use of natural uranium fuel without the need for enrichment.

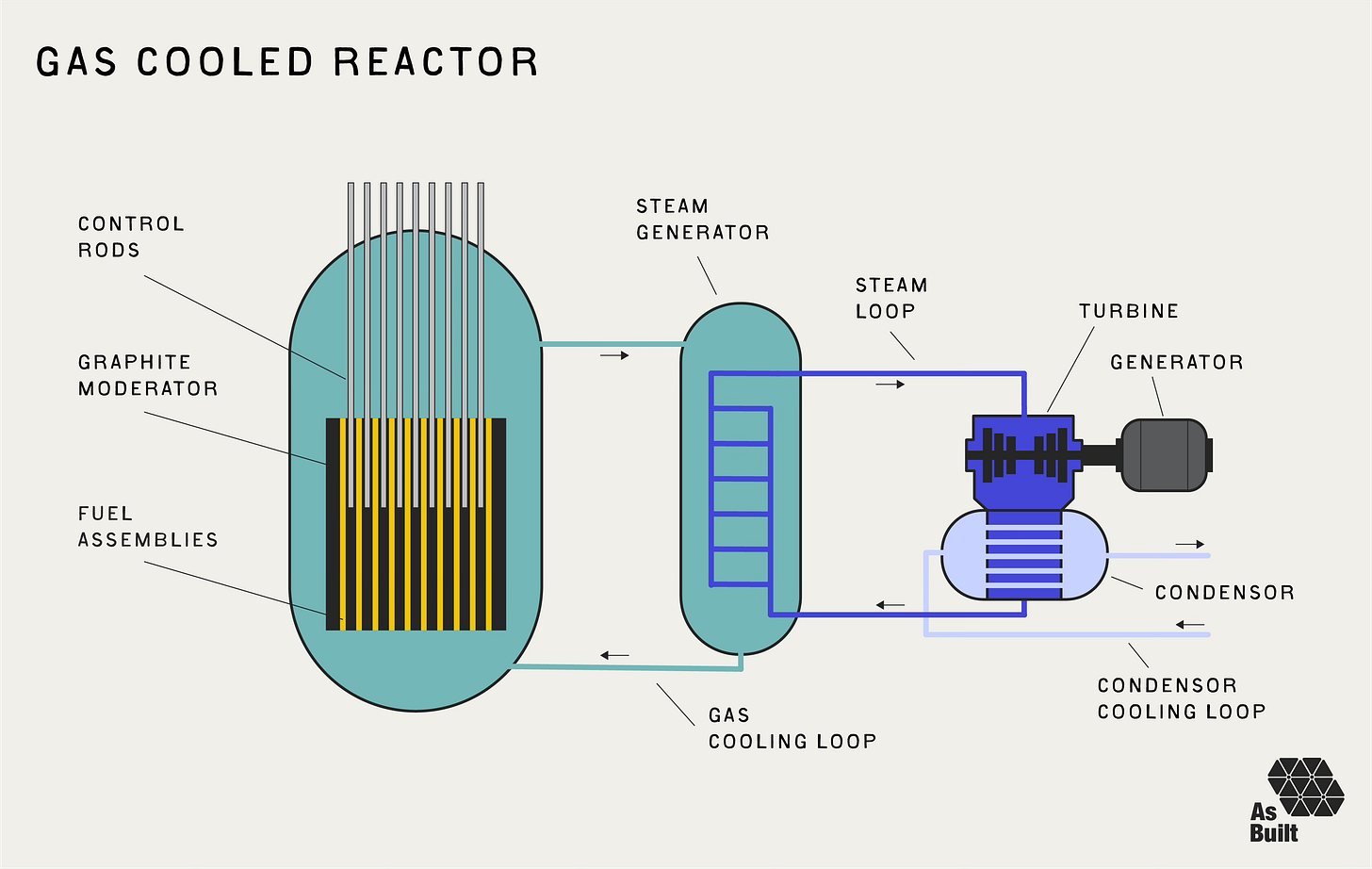

Gas Cooled Reactors use either carbon dioxide or helium as a coolant with solid graphite blocks for moderation. These reactors can achieve higher operating temperatures than water cooled designs.

Molten Salt Reactors use molten fluoride salts as both a fuel carrier and coolant. The fuel is dissolved directly in the liquid salt rather than formed into solid fuel rods.

Fast Reactors

Fast reactors do not use a moderator, allowing neutrons to remain at high energy. This unlocks two key capabilities. First, they can breed fuel. Fast neutrons convert fertile uranium-238 into fissile plutonium-239. Second, they can consume nuclear waste. These reactors can fission actinides that would otherwise remain radioactive for thousands of years.

The tradeoff comes in fuel requirements. Since fission is less probable with fast neutrons, we need a higher density of potential fission targets. Fast reactors need either highly enriched uranium (15-20% or higher) or plutonium to achieve criticality. Once operating, they can breed enough plutonium to refuel themselves and even fuel other reactors.

There are two primary types of fast reactors, and both are liquid cooled:

Sodium Fast Reactors use liquid sodium as a coolant, which has high heat transfer capability and minimal neutron moderating properties. However, liquid sodium is highly reactive with air and water, requiring significant safety systems.

Lead Fast Reactors use liquid lead/lead-bismuth as coolants. These also have high heat transfer and low neutron moderation. Lead-based coolants are mostly inert, making them safer options for plants. However, the substance is highly corrosive, requiring special materials.

There are a variety of gas cooled fast reactors in research and development. They operate similarly to gas cooled thermal reactors, but without the use of moderators. These designs can theoretically achieve very high temperatures with improved efficiency, but face challenges in maintaining adequate heat removal with low density gas. Since none are commercially deployed, they are not considered in detail here.

Building a Nuclear Reactor

Now that we’ve characterized the landscape, let’s dive into the details of the various subsystems.

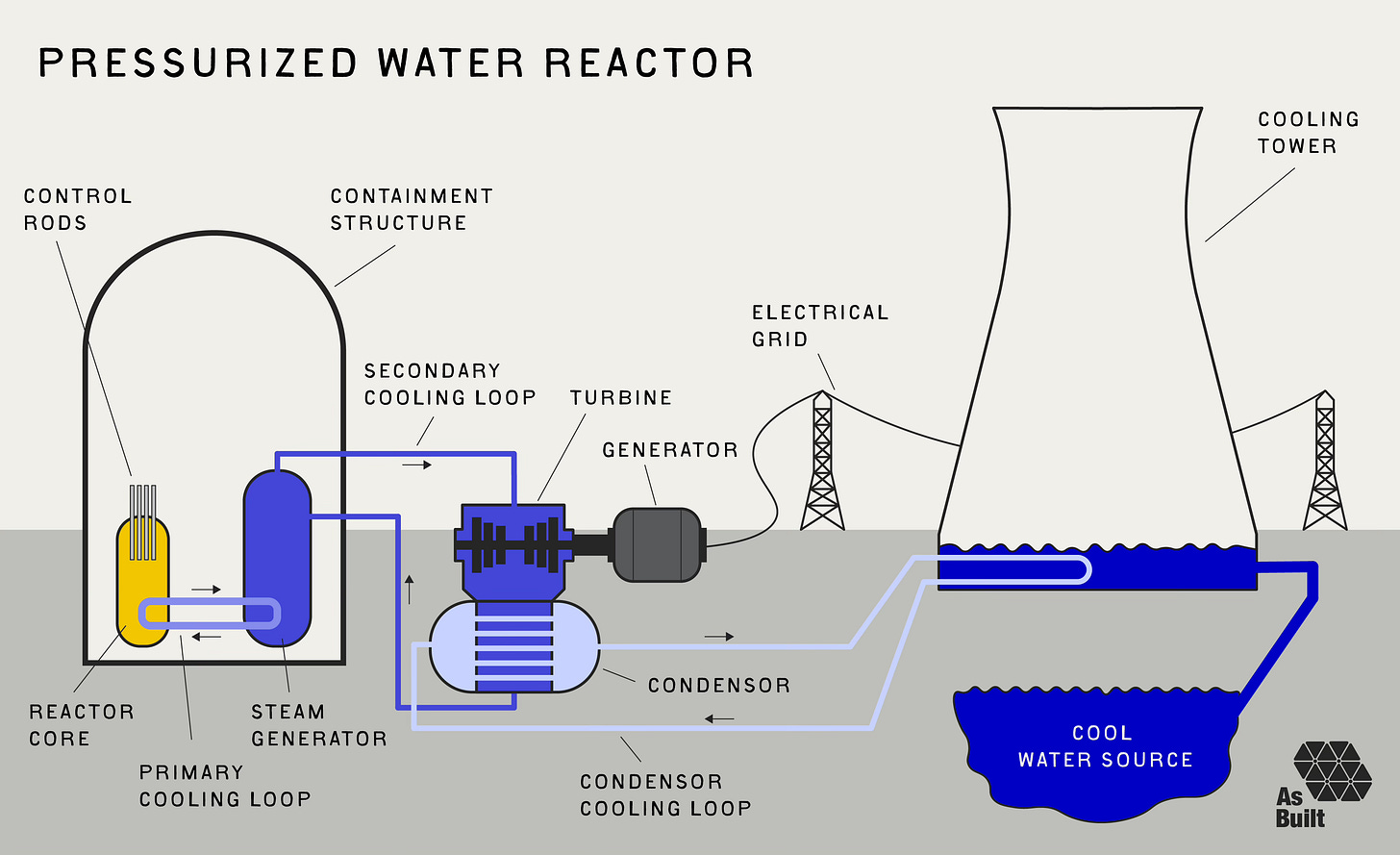

Of all architectures, PWRs are the most prevalent. They make up 74% of the global reactor fleet and generate 78% of worldwide nuclear power on a per Watt basis.

Their widespread deployment makes PWRs the logical example for this case study. PWR designs vary plant by plant, and here we’ll consider a generalized reactor for illustrative purposes.

Fuel

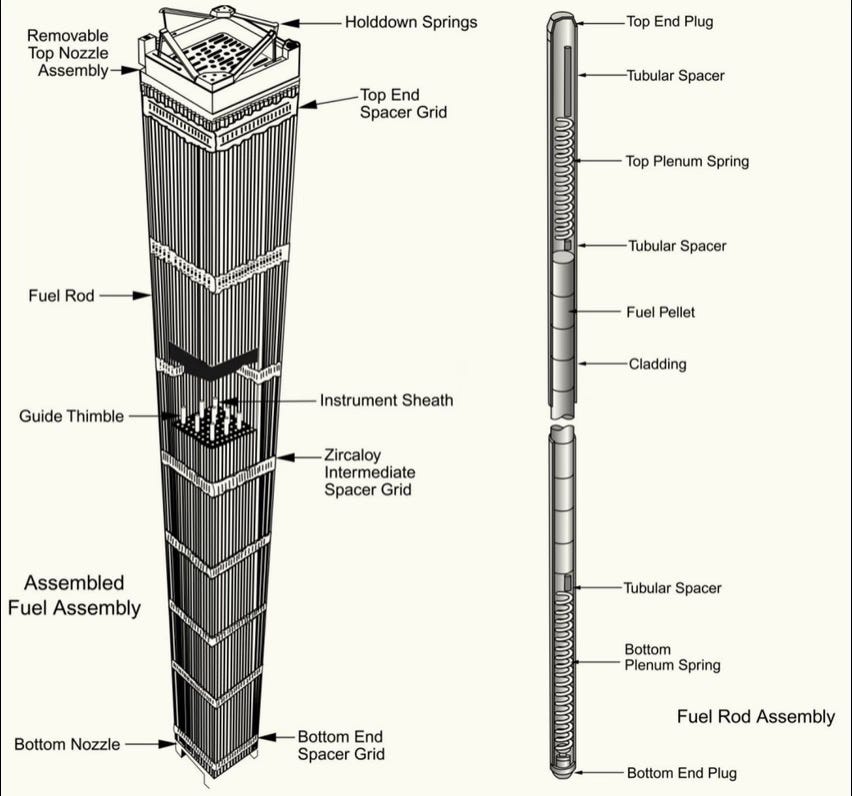

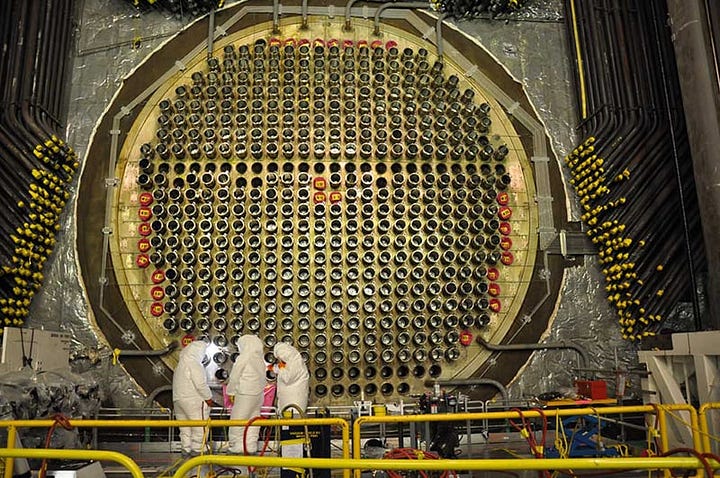

At the center of a nuclear reactor is the fuel assembly. A typical PWR core consists of approximately 200 assemblies arranged in a precise geometric pattern. Each fuel assembly is a 17 x 17 square array of long, narrow cylindrical rods. In this 289-position matrix, 264 positions contain fuel rods, 24 house guide tubes for control rods, and one is used for instrumentation.

Fuel rods are hollow zirconium alloy tubes about half an inch in diameter and roughly 12 feet long. Inside each rod, about 400 uranium dioxide pellets are stacked to form the fissile material. The uranium dioxide is enriched to 3-5% uranium-235, with the remainder being uranium-238.

Zirconium has an extremely low neutron absorption cross-section, so it steals very few neutrons from the fission process. The fuel rods are densely packed with roughly an eighth of an inch between them, creating channels for water to flow.

Moderator

PWRs use water as both a moderator and a coolant. It is pressurized to about 2,200 psi to prevent boiling. As the water flows around the fuel rod assemblies, it extracts heat, reaching temperatures of about 650°F. At the same time, its hydrogen atoms slow neutrons through repeated collisions.

Temperature creates a negative feedback loop in PWRs, providing inherent safety. As water heats up, its density decreases. This creates more space between hydrogen atoms, making neutron impacts less likely to occur. Fewer neutrons are slowed, and as a result, the fission rate decreases.

This decrease in power due to increase in temperature is a built-in safety feature that has helped PWRs gain regulatory approval and public acceptance worldwide.

Coolant

PWRs use a two-loop coolant design. The water that cools the fuel rod assemblies and doubles as a moderator is known as the primary loop. It becomes mildly radioactive as neutrons interact with the water molecules.

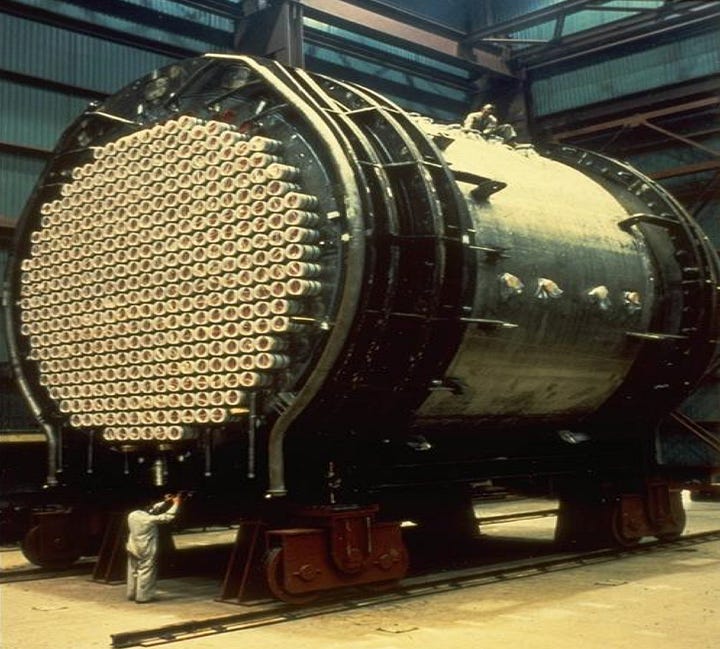

The primary loop carries heat from the fuel rod assemblies to a series of heat exchangers, known as steam generators. Here, the primary loop transfers heat to the secondary loop, which also uses water coolant. The secondary loop operates at lower pressure, around 1,000 psia, allowing the water to boil and create steam for turbine generators.

The two-loop design isolates radioactive materials from turbine systems and provides multiple barriers against the release of radioactive materials.

Power Generation

The secondary loop carries steam to conventional Rankine steam cycle generators. The hot steam flows over turbine blades, causing them to spin a generator and create electricity. After this, the steam passes through a condenser where it’s cooled back to liquid form before returning to the steam generator.

A third coolant loop provides condenser cooling, interfacing with the environment through seawater, cooling ponds, or cooling towers. This condenser loop is twice removed from the reactor core, ensuring no radioactive materials escape. The iconic nuclear cooling towers are part of this final heat rejection system.

Control

Lastly, reactors need to be controlled. We need ways to ramp power up, ramp it down, and shut it off in an emergency. We achieve this by controlling the number of neutrons that move through the core. More neutrons mean more fission and more power. Fewer neutrons mean the opposite. To adjust the neutron levels, we use neutron absorbers, which are materials that capture neutrons and prevent further fission.

PWRs use control rods that slide in and out of the 25 guide tubes in each fuel assembly. The control rods are hollow stainless steel tubes filled with a neutron absorbing material. Often, an 80% silver, 15% indium, and 5% cadmium alloy is used. This mixture is tuned to have a high absorption cross-section across a wide range of neutron energies.

Control rods are inserted from above by a drive mechanism that moves them vertically. The deeper the insertion, the more neutrons absorbed and the lower the reactor power.

The control rods are connected to the drive assembly via an electromagnetic coupling. It requires an electrical current to remain latched. If power is lost or operators perform an emergency shutdown, the coupling is released and the rods drop into the core within seconds. This gravity-assisted, failsafe shutdown is called a SCRAM, and is a cornerstone of nuclear safety.

PWRs can also dissolve boric acid directly in the coolant for fine reactivity control. Operators adjust boron concentration throughout the fuel cycle. It’s high at the beginning when fuel is fresh, and gradually reduced as the fuel depletes. This allows precise power adjustments without moving control rods.

Examining the Other Architectures

Building off the PWR example, we’ll examine other architectures to understand their differences and tradeoffs, starting with the other thermal reactors.

Light Water Reactors

As noted above, there are three types of light water reactors. PWRs and boiling water reactors (BWRs) use ordinary light water for both neutron moderation and heat removal. The Russian RBMK reactor uses light water as a coolant and graphite as a moderator. We’ve already covered PWRs extensively, so we’ll dive right into BWRs.

Boiling Water Reactors

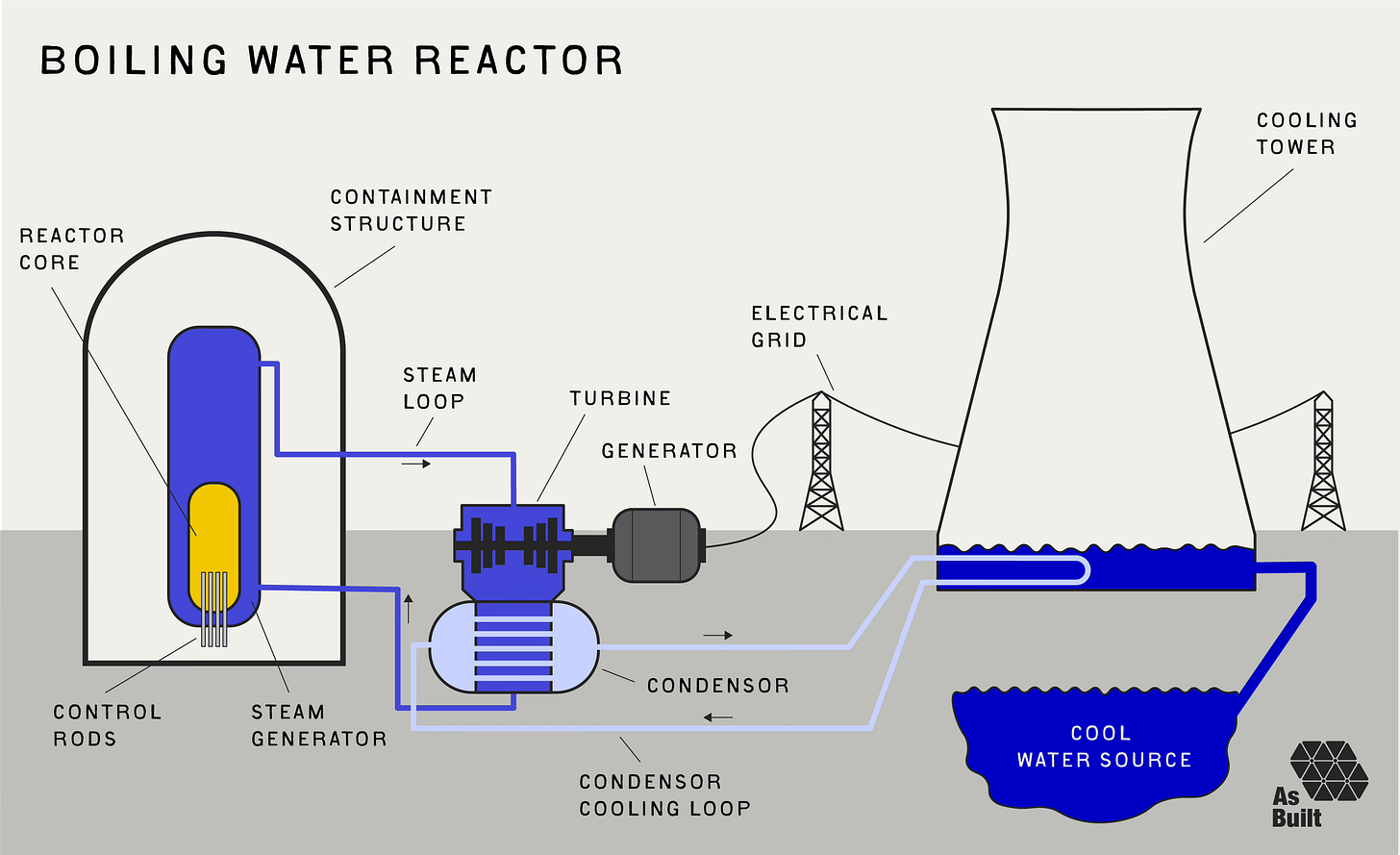

BWRs embrace what PWRs avoid. They allow water to boil in the core. This fundamental choice cascades through every aspect of the design. BWRs operate at 1,000 psi, about half the pressure of PWRs. At this pressure, water boils at approximately 545°F, converting to steam right in the reactor core.

As a result, BWRs don’t have the massive heat exchangers that define PWRs. The simplification eliminates an entire cooling loop worth of pumps, piping, and potential failure points, reducing costs and improving efficiency.

Yet this elegance brings unique challenges:

Turbine hall radiation: The steam carries radioactive fluids directly to the turbine, making it a radiation area. This complicates maintenance and requires extensive shielding.

Chemistry challenges: Without a secondary loop barrier, corrosion products from turbines flow directly through the core, depositing on fuel rods. BWRs also cannot use dissolved boron for reactivity control since it would corrode downstream equipment.

Control complexity: Boiling creates power instabilities as steam voids form and collapse unpredictably. This requires sophisticated monitoring to prevent dangerous oscillations.

Bottom mounted control rods: Control rods insert from below using hydraulics rather than gravity. If hydraulic systems fail, the rods cannot drop into shut down the reactor.

Larger pressure vessel: The reactor vessel must house not just the core but steam separators and dryers, making it significantly larger and more complex than PWR vessels.

Despite these challenges, forty three BWRs are operating worldwide, concentrated in Japan, the United States, and Sweden. Modern BWR designs address these vulnerabilities with passive safety systems. Natural circulation designs eliminate pumps entirely. Isolation condensers provide cooling without power. But the fundamental trade-off remains: mechanical simplicity in exchange for operational complexity.

RBMK Reactors

RBMKs represent a uniquely Soviet approach to reactor design, combining light water cooling with graphite moderation. RBMK stands for Reaktor Bolshoy Moshchnosti Kanalnyy, which translates to High Powered Channel Reactor.

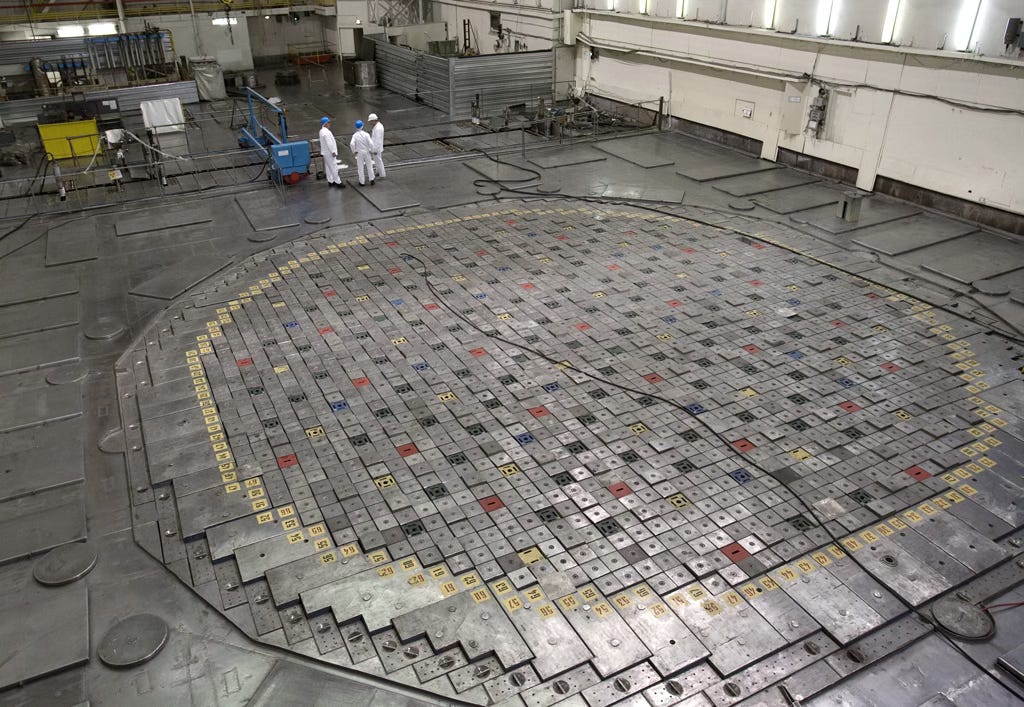

Unlike PWRs and BWRs that contain fuel in a single pressure vessel, RBMKs use thousands of individual pressure tubes running vertically through a massive graphite block. Each tube contains water cooled fuel assemblies, while the surrounding graphite moderates neutrons.

This architecture enables two strategic advantages. First, operators can refuel individual channels without shutting down the reactor, maintaining high availability and continuous plutonium production. Second, the design uses relatively low enriched uranium, with graphite’s low neutron absorption enabling criticality.

However, this design harbors a fatal flaw: a positive void coefficient. In most reactors, steam voids slow the reaction because water moderates neutrons. But RBMKs use graphite for moderation, while water mainly absorbs neutrons. When water turns to steam, fewer neutrons are absorbed, but moderation continues unchanged. This accelerates the reaction and can trigger runaway power surges.

This characteristic, combined with control rod design flaws and operator errors, led to the Chernobyl disaster. During a 1986 safety test, operators withdrew too many control rods to overcome xenon poisoning from low power operation. When they attempted an emergency shutdown, a design flaw in the control rods briefly increased reactivity. The positive void coefficient amplified this spike into a steam explosion that destroyed the reactor.

Eight RBMK reactors still operate, all in Russia, with significant safety modifications including modified control rods and operating restrictions to prevent the conditions that enabled Chernobyl. No new RBMKs are under construction.

Heavy Water Reactors

Pressurized Heavy Water Reactors (PHWR) operate in the thermal neutron spectrum, but approach neutron management differently. They use heavy water as a moderator and coolant. Heavy water is deuterium oxide (D₂O), which is water made with deuterium, a heavy isotope of hydrogen containing both a proton and a neutron in its nucleus.

The key to PHWR design lies in deuterium’s superior neutron economy. While ordinary hydrogen is an excellent neutron moderator due to its low mass, it also absorbs neutrons, removing them from the fission process. Deuterium still slows neutrons effectively but absorbs far fewer. It is about 600 times less likely to capture a neutron than regular hydrogen. This efficiency enables PHWRs to achieve criticality with natural uranium (0.7% uranium-235), eliminating the need for enrichment.

The trade-off is heavy water itself. Deuterium is naturally occurring, but it makes up just 0.016% of seawater. The process of concentrating it is both expensive and time consuming. A typical 700 MW PHWR requires about 500 tons of heavy water, which represents about 10%-20% of the initial plant capital cost. However, if managed properly, the heavy water inventory lasts for decades.

CANDU Reactors

The most widely deployed PHWR design is the Canada Deuterium Uranium (CANDU) reactor. At its heart sits the calandria, which is a large horizontal cylindrical tank filled with low-pressure heavy water to serve as a moderator.

Between 380 and 480 horizontal channels run through the calandria, each consisting of two concentric tubes. The inner pressure tube, often made of zirconium-niobium alloy, contains the fuel bundles and high-pressure coolant at 600°F. The outer calandria tube isolates the hot pressure tube from the cool moderator. A carbon dioxide-filled gap between the tubes provides thermal insulation.

This unique architecture enables online refueling, which is a defining CANDU advantage. While the reactor operates at full power, a refueling machine latches onto individual pressure tubes, removes spent fuel bundles from one end, and inserts fresh ones from the other.

Forty six PHWR reactors currently operate worldwide. Canada initially developed the technology to leverage its uranium resources without enrichment capability. Later, India adopted it after being excluded from enrichment technology following its 1974 nuclear test. Both nations have since become major CANDU operators.

Gas Cooled Reactors

Moving beyond water based systems entirely, gas cooled reactors enable higher operating temperatures and improved thermodynamic efficiency. Carbon dioxide and helium are common coolant candidates. Neither provides neutron moderation. Instead, that is accomplished via solid graphite blocks in the reactor core.

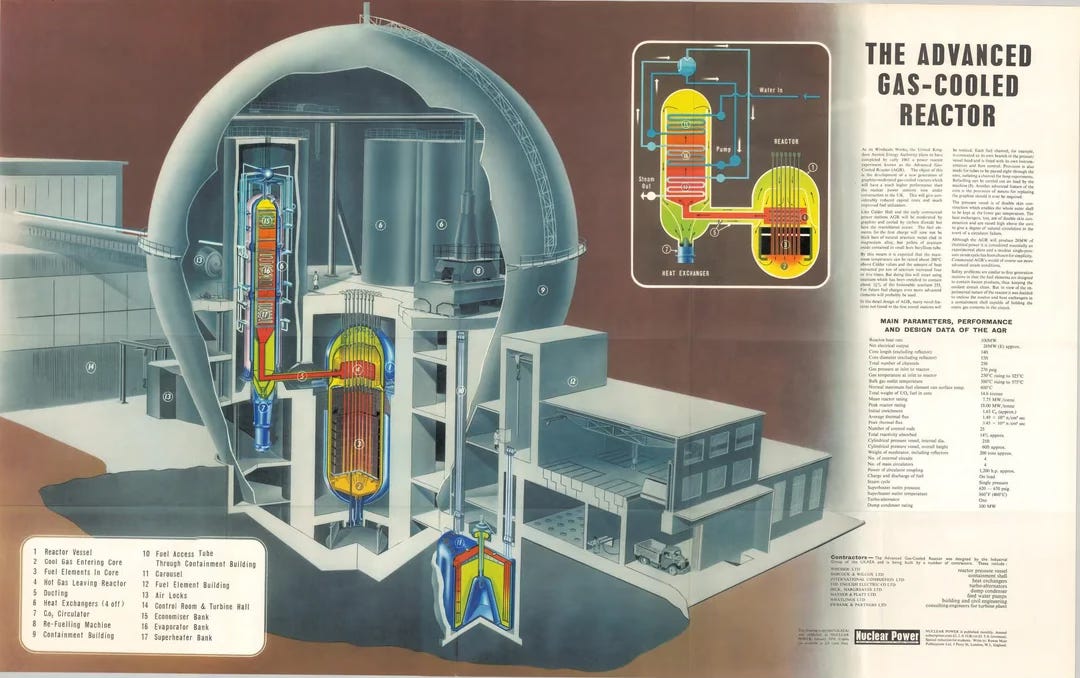

Magnox and Advanced Gas Cooled Reactors The United Kingdom pioneered commercial gas cooled reactors in the 1950s with Magnox reactors, which were named for their magnesium-aluminum alloy fuel cladding. These reactors arranged natural uranium fuel rods within vertical channels drilled through a massive graphite core. Carbon dioxide coolant, pressurized to 100-300 psi, flowed through these channels, extracting heat while the surrounding graphite moderated neutrons. The low neutron absorption of both carbon dioxide and graphite enabled criticality with natural uranium.

Twenty-six Magnox reactors operated successfully for decades, but their low operating temperature limited efficiency. The UK addressed this with Advanced Gas Cooled Reactors (AGRs) in the 1960s. AGRs retained the graphite core and CO₂ coolant but switched to 2.5-3.5% enriched uranium. This enabled outlet temperatures of 1200°F and improved thermal efficiency.

However, this performance came with challenges. Hotter carbon dioxide becomes corrosive, attacking steel components. Additionally, decades of neutron bombardment cause the graphite moderator to shrink and crack. As channels distort, fuel assemblies can jam, and control rod insertion becomes uncertain. Of the fourteen AGRs built, eight continue operating in the UK, but graphite degradation limits their remaining lifespans.

High Temperature Gas Reactors (HTGR) Modern HTGR designs use helium as a coolant, with a target temperature of 1380°F. This temperature is hot enough for direct use as a process gas in some industrial applications, such as hydrogen production or steelmaking.

These reactors are often planned to use TRi-structural ISOtropic (TRISO) fuel. This type of fuel consists of tiny uranium kernels wrapped in multiple ceramic layers that contain fission products even at extreme temperatures.

In some pebble bed designs, tennis-ball-sized graphite spheres containing thousands of TRISO particles flow continuously through the core like gumballs in a machine. Fresh fuel is added at the top, and spent fuel is removed at the bottom. This enables refueling without shutdown and inherent safety.

The trade-off is power density. Helium’s low density means it removes heat poorly compared to water, requiring larger cores for the same power output. An HTGR producing 600 MW might have a core volume three times larger than an equivalent PWR. This size penalty, combined with TRISO fuel fabrication complexity, has limited commercial deployment despite the technology’s elegance. China operates the world’s only HTGR.

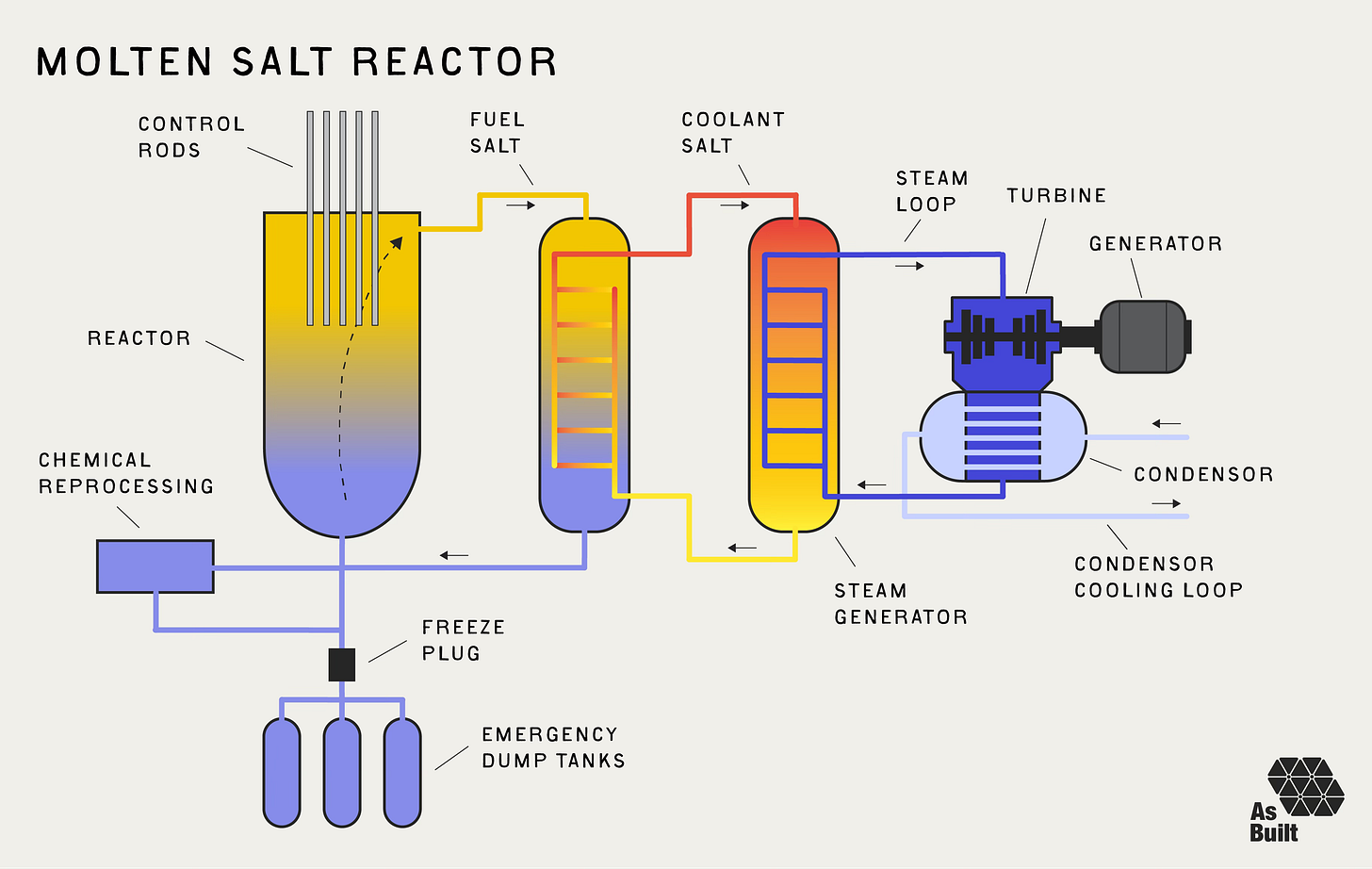

Molten Salt Reactors

Molten salt reactors (MSR) radically depart from conventional reactor design. Instead of solid fuel rods, they dissolve fuel directly in molten liquid fluoride salts. This is typically a mixture of lithium fluoride, beryllium fluoride, and uranium tetrafluoride. This liquid serves as both fuel and coolant, flowing through the reactor core at 1200°F-1300°F while remaining at atmospheric pressure. Oak Ridge National Laboratory (ORNL) proved the concept with the 8 MW Molten Salt Reactor Experiment (MSRE) from 1965 to 1969.

The architecture offers compelling advantages. Without pressure vessels or water that can flash to steam, MSRs achieve walk-away safety through physics alone. A freeze plug sits at the reactor’s lowest point. This is essentially a section of salt pipe actively cooled to keep it solid. If power fails or temperatures exceed limits, the plug melts and gravity drains the fuel into subcritical geometry tanks where passive cooling prevents damage. No pumps, valves, or operator action are required.

Liquid fuel also enables continuous processing. Gaseous fission products like xenon and krypton bubble out naturally, eliminating the neutron poisoning that plagues solid-fuel reactors. Operators can adjust fuel composition on the fly, adding fresh uranium, removing fission products, or changing the uranium-plutonium ratio. Theoretically, an MSR could run for decades without shutdown, achieving near complete fuel burnup.

Yet, materials challenges are limiting. The fuel salt, while excellent at retaining most fission products, is viciously corrosive. Fluoride salts attack virtually every known alloy, leaching chromium from stainless steel and causing intergranular cracking. ORNL developed Hastelloy-N specifically for MSRE, but even this specialized nickel superalloy suffered embrittlement after prolonged exposure.

There are also unique control and safeguard challenges. Without fuel assemblies to count, proliferation monitoring becomes complex.

No commercial MSR operates today. China is developing a pilot plant, while ventures in Canada and the United States pursue various designs.

Fast Reactors

Fast reactors operate at the opposite end of the neutron spectrum. Without moderators, neutrons maintain their high energies. As described above, this enables breeding by converting uranium-238 to plutonium-239 and waste burning. But it requires high fissile content: 15-20% enriched uranium or plutonium to achieve criticality.

Only two commercial fast reactors operate worldwide, both are in Russia, and both are sodium cooled.

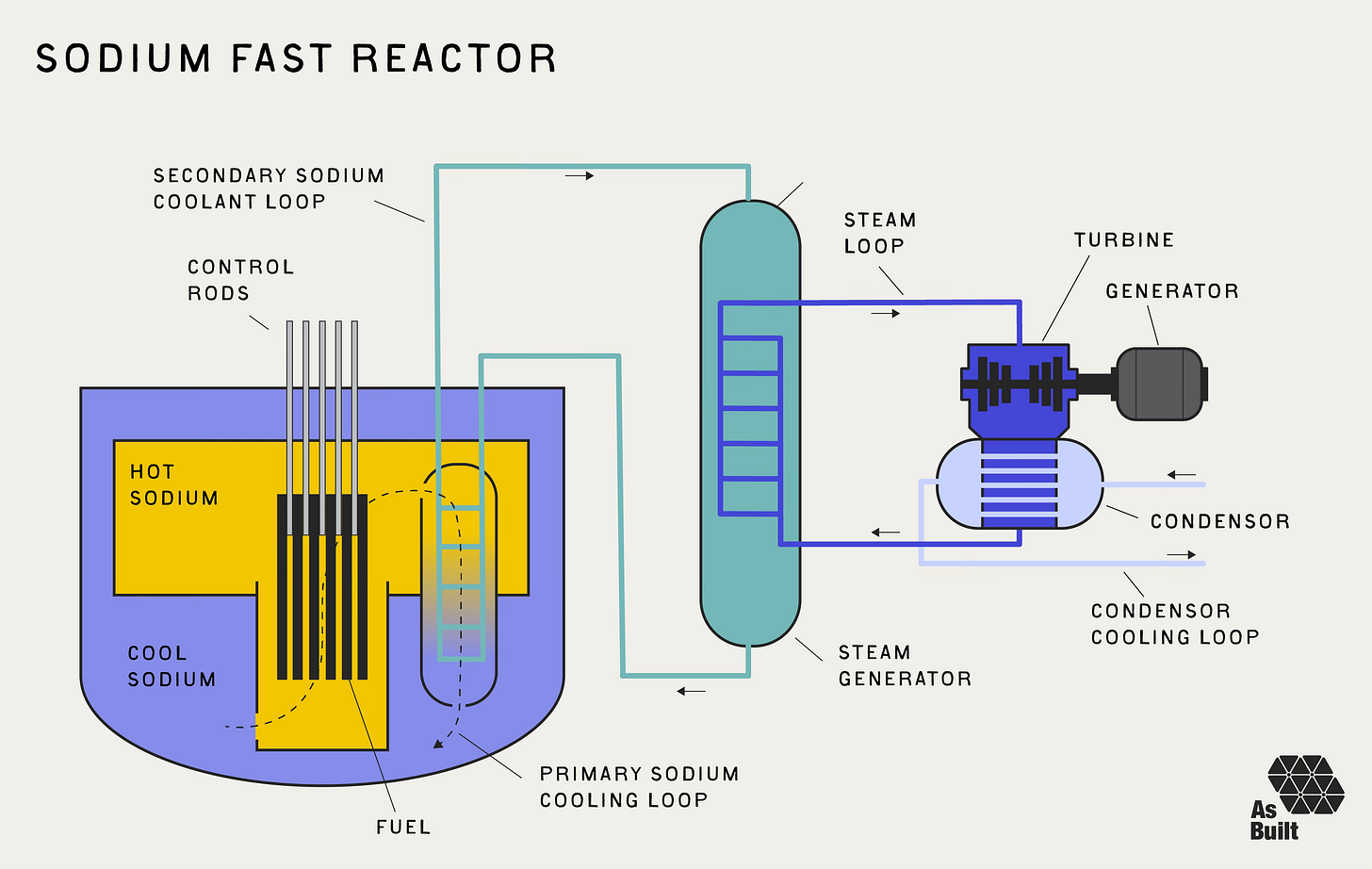

Sodium Fast Reactors (SFR)

Liquid sodium is widely used in fast reactors for good reasons. At atmospheric pressure, it remains liquid from about 208°F up to 1621°F, enabling reactor coolant circuits to operate at low pressure. Its high thermal conductivity and favorable heat transfer properties support high power densities and efficient heat removal. Sodium is a weak neutron moderator and has a low neutron absorption cross section, helping maintain a fast neutron spectrum essential for breeding.

The fundamental challenge is sodium’s violent reactivity with water and air. A pinhole leak sprays sodium that ignites on contact with air, burning at 1,832°F. Water contact triggers explosive reactions, producing hydrogen gas and caustic sodium hydroxide. This drives complex three-loop designs: radioactive primary sodium transfers heat to non-radioactive intermediate sodium, which then generates steam. Each interface is a potential failure point.

Engineering solutions exist, but they add complexity. Argon cover gas prevents air contact. Double-walled piping with leak detection catches failures before they escalate. Dump tanks allow rapid draining during emergencies.

Russia’s BN-600 SFR has operated since 1980, surviving multiple sodium leaks and fires. Its successor, BN-800, began operation in 2014 with improved safety features. France’s Superphénix and Japan’s Monju SFRs both shut down after repeated sodium leaks and operational problems.

Lead Fast Reactors (LFR)

Lead reactors avoid sodium’s fire hazard, using either lead or lead-bismuth as the coolant. Lead doesn’t burn and remains liquid from 621°F to 3,160°F. The Soviet Alfa-class submarines demonstrated the potential. Compact lead-bismuth reactors propelled the submarines to a remarkable 42 knots underwater.

However, lead-bismuth creates polonium-210 through neutron capture, which is one of the most toxic substances known. Just one millionth of a gram is lethal if inhaled. At standard operating temperatures, it volatilizes, contaminating the entire system.

When maintenance was necessary, crews in special suits worked in shifts measured in minutes. Lead also corrodes steel aggressively, dissolving nickel and redepositing it elsewhere, plugging channels. Several Soviet submarines were lost when coolant solidified in port after heating failures.

Russia is building the BREST-300 plant, which uses pure lead to avoid polonium, and the plant is slated to start operating in 2026.

Small Modular Reactors

Small Modular Reactors (SMRs) are a unique approach to reactor design and production. Nearly any of the architectures discussed above can be adapted to this format. SMRs bet on manufacturing over construction. The reactors are typically smaller (under 300 MW), built in a factory, and then shipped to the site for installation.

From a manufacturing perspective, the method promises more controlled manufacturing environments, parallel production, and higher quality control.

Operationally, deploying modular units also has benefits. Plants can be incrementally constructed through the installation of a series of smaller reactors. This enables more gradual capital expenditure, mitigating financial and operational risk. Additionally, small units can be co-located directly with the infrastructure they power, such as airports, datacenters, or military installations.

However, the unit cost of smaller reactors may suffer from reduced economies of scale, and it’s not yet clear what production volume is required to overcome this dynamic. Additionally, there may be a heightened proliferation risk associated with a more distributed footprint.

A substantial number of SMR programs are underway, particularly in the U.S. These range from kilowatt-level units for defense installations to grid-scale arrays of modular units that provide commercial power.

What Actually Gets Built

The nuclear industry’s architecture selections tell two stories. The first is convergence: 306 of 416 operating reactors are PWRs, a 74% dominance that traces directly to submarine hulls. The second is persistence: despite this overwhelming convergence, alternative architectures refuse to disappear.

PWRs won through compound advantages. Admiral Rickover’s submarine program debugged the technology with naval discipline and unlimited budgets. When nations needed civilian power, they adapted what worked underwater. Each plant built deepened the moat: more operational data, refined supply chains, experienced workers, proven regulations.

Yet the alternatives endure where strategic value exceeds economic penalty. Canada’s CANDU reactors trade complexity for fuel independence. Russia’s fast reactors enabled closed fuel cycles. Britain’s aging AGRs soldier on despite graphite degradation. These aren’t mistakes. They’re different answers to the same question, shaped by unique constraints.

The pattern reveals a fundamental tension in nuclear technology. Standardization brings efficiency, learning curves, and cost reduction. But it also creates dependencies on enrichment infrastructure, foreign fuel supplies, and technologies optimized for other nations’ needs.

This tension isn’t a flaw to be fixed but a reality to navigate. The winner won’t be the best reactor physics can produce, but the one that best balances technical merit, economic viability, and strategic value for the nation that builds it. In nuclear power, these three don’t always align. And that’s why, after seven decades, we still see such radically different machines splitting atoms for the same fundamental purpose.

General References

International Atomic Energy Agency. PRIS: Power Reactor Information System (Overview). Vienna: IAEA, n.d. Accessed August 25, 2025. https://www-pris.iaea.org/

World Nuclear Association. “Nuclear Power in France.” Updated 2025. Accessed August 25, 2025. https://world-nuclear.org/information-library/country-profiles/countries-a-f/france.aspx.

World Nuclear Association. “Nuclear Power in the United Kingdom.” Updated 2025. Accessed August 25, 2025. https://world-nuclear.org/information-library/country-profiles/countries-t-z/united-kingdom.aspx.

World Nuclear Association. “High-Temperature Gas-Cooled Reactors.” Accessed August 25, 2025. https://world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/advanced-nuclear-power-reactors.aspx#HTGR.

World Nuclear News. “China’s HTR-PM Achieves Commercial Operation.” December 2023. Accessed September 23, 25, 2025. https://www.world-nuclear-news.org/Articles/Chinas-HTR-PM-achieves-commercial-operation.

Westinghouse Electric Company. “RFA-2 Fuel Design.” Data sheet, ca. 2016. Accessed August 25, 2025. https://westinghousenuclear.com/media/yaln2un5/rfa-2-fuel-design.pdf.

University of Wisconsin. “Pressurized Water Reactor Pressure Vessels (Lecture 37).” 1997. Accessed August 25, 2025. https://fti.neep.wisc.edu/fti.neep.wisc.edu/neep423/FALL97/lecture37.pdf.

Massachusetts Institute of Technology (OpenCourseWare). “PWR Description.” Engineering of Nuclear Systems (22.06), lecture slides, 2010. Accessed August 25, 2025. https://mitocw.ups.edu.ec/courses/nuclear-engineering/22-06-engineering-of-nuclear-systems-fall-2010/lectures-and-readings/MIT22_06F10_lec06a.pdf.

International Atomic Energy Agency. Pressurized Water Reactor Simulator (Training Course Series No. 22). Vienna: IAEA, 2003. Accessed August 25, 2025. https://www-pub.iaea.org/MTCD/Publications/PDF/TCS-22_2nd_web.pdf.

U.S. Nuclear Regulatory Commission. “Moderator Temperature Coefficient of Reactivity (Glossary).” Accessed August 25, 2025. https://www.nrc.gov/reading-rm/basic-ref/glossary/moderator-temperature-coefficient-of-reactivity.html.

U.S. Nuclear Regulatory Commission. “SCRAM (Glossary).” Accessed August 25, 2025. https://www.nrc.gov/reading-rm/basic-ref/glossary/scram.html.

Mitsubishi Heavy Industries. “PWR Fuel.” Mitsubishi Nuclear Fuel Co., Ltd. Accessed August 25, 2025. https://www.mhi.com/group/mnf/products/pwr.html.

World Nuclear Association. “Nuclear Power in Canada.” Updated 2025. Accessed August 25, 2025. https://world-nuclear.org/information-library/country-profiles/countries-a-f/canada.aspx.

Oak Ridge National Laboratory. “History | Molten Salt Reactor Experiment (MSRE).” Accessed August 25, 2025. https://www.ornl.gov/molten-salt-reactor/history.

Oak Ridge National Laboratory. “MSRE Operating History (ORNL-TM-3229).” 1970. Accessed August 25, 2025. https://moltensalt.org/references/static/downloads/pdf/ORNL-TM-3229.pdf.

World Nuclear Association. “Lead-cooled Fast Reactors (LFR).” Accessed August 25, 2025. https://world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/advanced-nuclear-power-reactors.aspx#LFR.

Generation IV International Forum (via OECD/NEA). Sodium-Cooled Fast Reactor (SFR) Systems. Paris: OECD/NEA, various. Accessed August 25, 2025. https://www.gen-4.org/gif/jcms/c_9350/sodium-cooled-fast-reactor-sfr.

World Nuclear News. “Beloyarsk BN-600 Fast Neutron Reactor Gets 15-Year Extension.” April 2025. Accessed August 25, 2025. https://www.world-nuclear-news.org/articles/beloyarsk-bn-600-fast-neutron-reactor-gets-15-year-extension.

World Nuclear News. “BN-600 Licensed to Operate Until 2025.” April 2020. Accessed August 25, 2025. https://www.world-nuclear-news.org/Articles/BN-600-licensed-to-operate-until-2025.

International Panel on Fissile Materials (Hui Zhang). “China Started Operation of its First CFR-600 Breeder Reactor.” December 15, 2023. Accessed August 25, 2025. https://www.belfercenter.org/research-analysis/china-started-operation-its-first-cfr-600-breeder-reactor.

International Atomic Energy Agency. “Small Modular Reactors (SMRs).” Accessed August 25, 2025. https://www.iaea.org/topics/small-modular-reactors.

Elsevier (ScienceDirect). “Experiments on Silver-Indium-Cadmium Control Rod Failure during Severe Accidents.” Annals of Nuclear Energy 94 (2016): 268–284. Accessed August 25, 2025. https://www.sciencedirect.com/science/article/pii/S0306454916304455.

U.S. Nuclear Regulatory Commission. “Safety Evaluation—Control Rod Assemblies: Use of Hafnium or Ag-In-Cd.” ML20247B696, 2020. Accessed August 25, 2025. https://www.nrc.gov/docs/ML2024/ML20247B696.pdf.